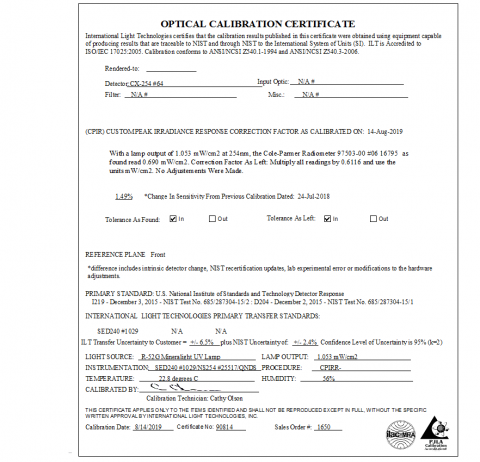

As light meter calibration specialists all g r labs light meter calibration services are traceable to the national bureau of standards nist with a 0 5 in house standard for radiometric calibrations and an in house 1 0 traceability for photometric calibrations.

Light meter calibration procedure.

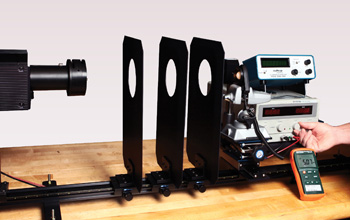

Our light meter calibration procedure requires our experienced technicians to take measurements by direct comparison to a calibrated standard meter and reference source.

Iso 100 in the external exposure meter and the camera and make sure that all correction values are at 0.

Light meter calibration light meters are utilized in a variety of industries and applications including photography cinematography osha compliance security quality assurance photosensitive materials regulatory requirements process controls and clean room standards.

If you need to maintain the accuracy of your instruments then you need light meter calibration services from acs calibration.

Professional light intensity lux meter that measures illumination levels in lux.

Our light meter calibration processes ensure that your instruments meets engineering machining parts design quality control and inspection requirements.

What actually happens in our 365nm standard for example is that the.

This data is then stored for easy 24 7 access within gagesuite our cloud based calibration management system.

In order for this meter to be exact you need to perform calibration procedure described in the apps s info screen.

The light meter then gathers the reflected or incident light levels as per the type used.

The 3 sigma accuracy to the calibrated probe is 3 0 maximum but g r labs standard is a 1 0 window from calibration to calibration.

Set the same iso value e g.

Multiple test points are taken across the full range of the device at intervals based on type of equipment.

An incident meter should be pointed toward the camera.

To calibrate your meter we recommend the following method.

We state our traceability to our in house 0 5 nist standard as 3.

This is to allow for the transfer from the nist standard to our secondary standards and then the transfer to the probe being calibrated.

Your exposure should be at a 2 8 or very close to it.

You ll be confident knowing that your instruments will provide accurate measurements.

If you are calibrating an incident meter use a flat disk hold the meter in front of the gray card and pointed at the camera.